SURFACE WATER TREATMENT TECHNOLOGY (Part I)

EFFECTIVENESS OF MULTIBEAM MIXING TECHNOLOGY IN 3D HYDRAULIC FLOC CREATION REACTION IN SURFACE WATER TREATMENT PLANT

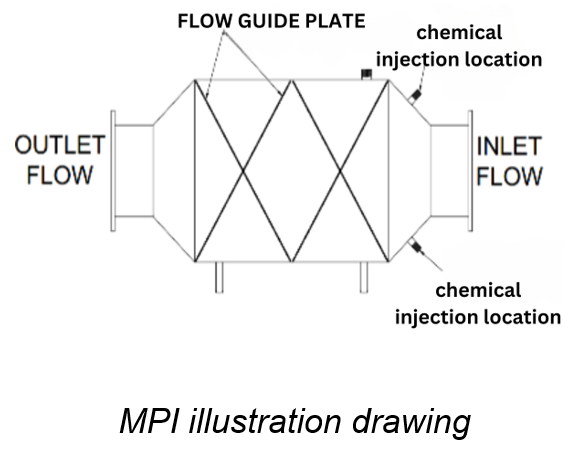

Multi Point Injection (MPI): a new invention by Dr. Rusnandi Garsadi. In this technology, kinetic energy is the energy source used to mix chemicals evenly within 1 to 2 seconds. Flow deflectors are installed inside the mixer, causing the water flow to continuously change direction, creating turbulent flow. Additionally, the Multi-Point Injection (MPI) with 4 chemical injection points ensures that the dosage of coagulant or PAC is almost 100% mixed without any loss. Current surface water treatment systems typically use an average PAC dosage of 20 to 30 g/m3, depending on the turbidity of the source water. However, when applying MPI in the treatment process, the PAC consumption can be reduced to 10 to 15 g/m3.

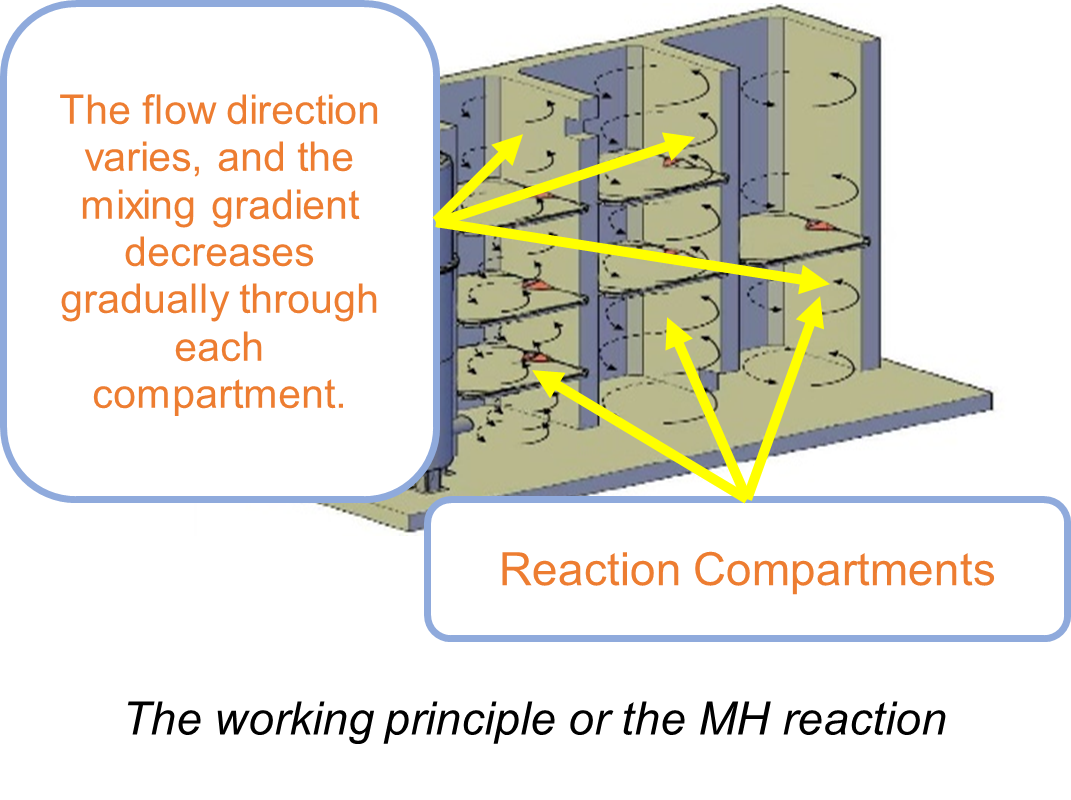

Micro Hydraulic 3-D reaction technology divides the flocculation reaction into smaller compartments. As we know, the initial two stages, namely coagulant mixing and floc formation, are crucial in the surface water treatment process. If the floc does not settle well and the flocs are not large enough, the sedimentation and filtration stages will be ineffective, resulting in poor water quality, reduced system capacity, and increased chemical consumption.

Therefore, in each compartment, hydraulic vortices with different calculated intensities flow through flow deflectors, gradually decreasing from compartment 1 to 8 (coagulation time approximately 15 minutes) to create larger and easily settleable flocs. Compartments 9 to 12 serve as stabilizing compartments to prevent floc breakage. This reaction process utilizes the maximum capacity of the existing layout and structure, resulting in the highest water quality. The existing capacity can be increased by 2 to 3 times, and the chemical dosage required will be significantly reduced.

For water treatment plants that have been using traditional treatment technologies, the implementation of Micro Hydraulic technology can significantly increase the system’s capacity by 2 to 3 times compared to the original design. This can be achieved without altering the existing layout and infrastructure of the treatment plant, resulting in low investment costs. Additionally, the chemical consumption during operation is significantly reduced.